Our story begins in 1964, when we started to manufacture our first manual glass washing machines with brushes in a small factory.

Since then, our production range has expanded considerably and we have consolidated our technical competences in the professional washing industry. We professionally design and manufacture the whole of our washing machine range: glass washers, front-loading dishwashers, passthrough dishwashers, conveyor rack dishwashers, with rack and belt system, pot washers and container washers. Each of the dishwashers we produce is put through strict tests to verify its operaBng efficiency and conformity to safety standards.

Today, we are a leading manufacturer on the expanding professional washing marketplace. Over the past 10 years, we have produced more than 200.000 dishwashers in our factory of 160.000 ft2 production site.

|

Since 2009, we have introduced the voluntary GS-TUV mark to guarantee our dishwashers, because quality should be certified and guaranteed. Our quality principle is not merely bound to perfect washing results but also and above all to guaranteeing the safety of the dishwasher itself. TUV SUD guarantees the safety of the product, which is assessed in terms of its overall aspects: mechanical and electrical safety, toxicity and flammability. It guarantees the operational efficiency declared by the manufacturer and that the specificaBons are maintained over time. It excludes products of poor technical content or whose credibility is uncertain. It guarantees that the products cerBfied comply with laws and European Directives and above all that they are built by a manufacturer that is constantly supervised; the authority obliges manufacturers to continually demonstrate that their organisation meets the basic principles guaranteed by an efficient quality system ( repeatability). |

|

Ecologic Sustainability

We believe that the ecologic sustainability of a business focused on environment-friendliness has to be proven with real facts.

In fact, with this in mind, we have equipped our production facilities with a photovoltaic system to produce electricity that has a rated capacity of 273 KW, which is equivalent to an input of 308.000 KW/year; this fully saBsfies all of our energy needs.

Furthermore, a solar panel heating system enables us to produce the hot water required to test our machines at the end of the producBon line.

We have of course developed systems for our machines that cut-down on the consumption of energy, water and washing products, as well as heat recovery devices like the CRV system and HP heat pumps.

Quality control

High Tech innovation

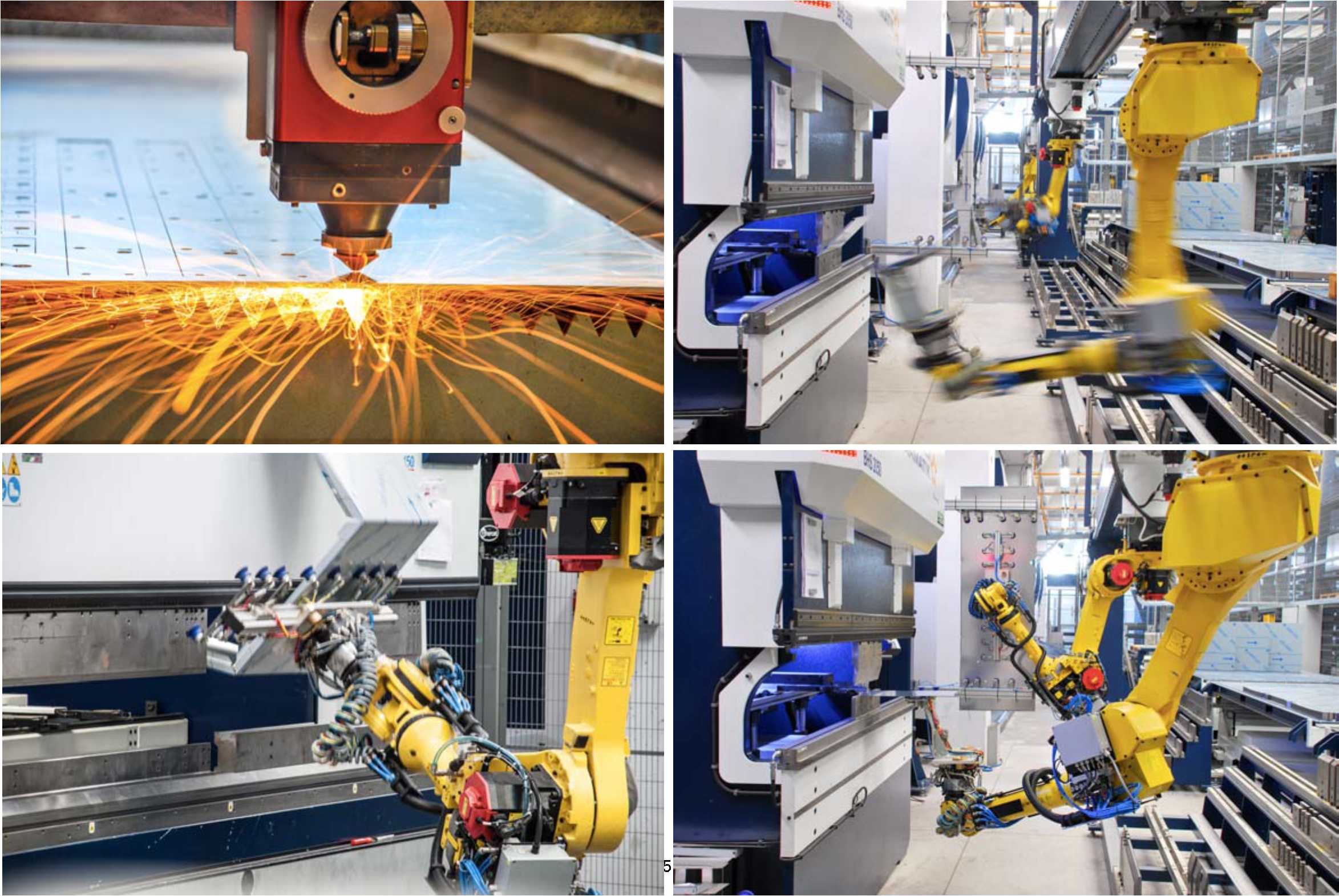

The designed system is an absolute innovation, not just in the field of industrial dishwashers.

A whole hi-tech production line has been built to produce products that wash to perfection in very short times.

Innovative robotic system measuring 90 meters in length to produce dishwashers frames, made up of:

1- laser-cutting systems.

2 - synchronized bending presses.

3 - bending and sorting robots.

4 - robotic plasma-welding stations.

5 - roll forming punching machine

6 - hydraulic presses

All this machinery is integrated with a Smart warehouse system made up of 120 compartments with unmanned "lights out" operation and distribution shuttle.

|

DISHWASHERS UNDERCOUNTERS |

ADD-ON

|

SUPPORT |

|

Copyright 2016 UNIVERCLEAN LTD